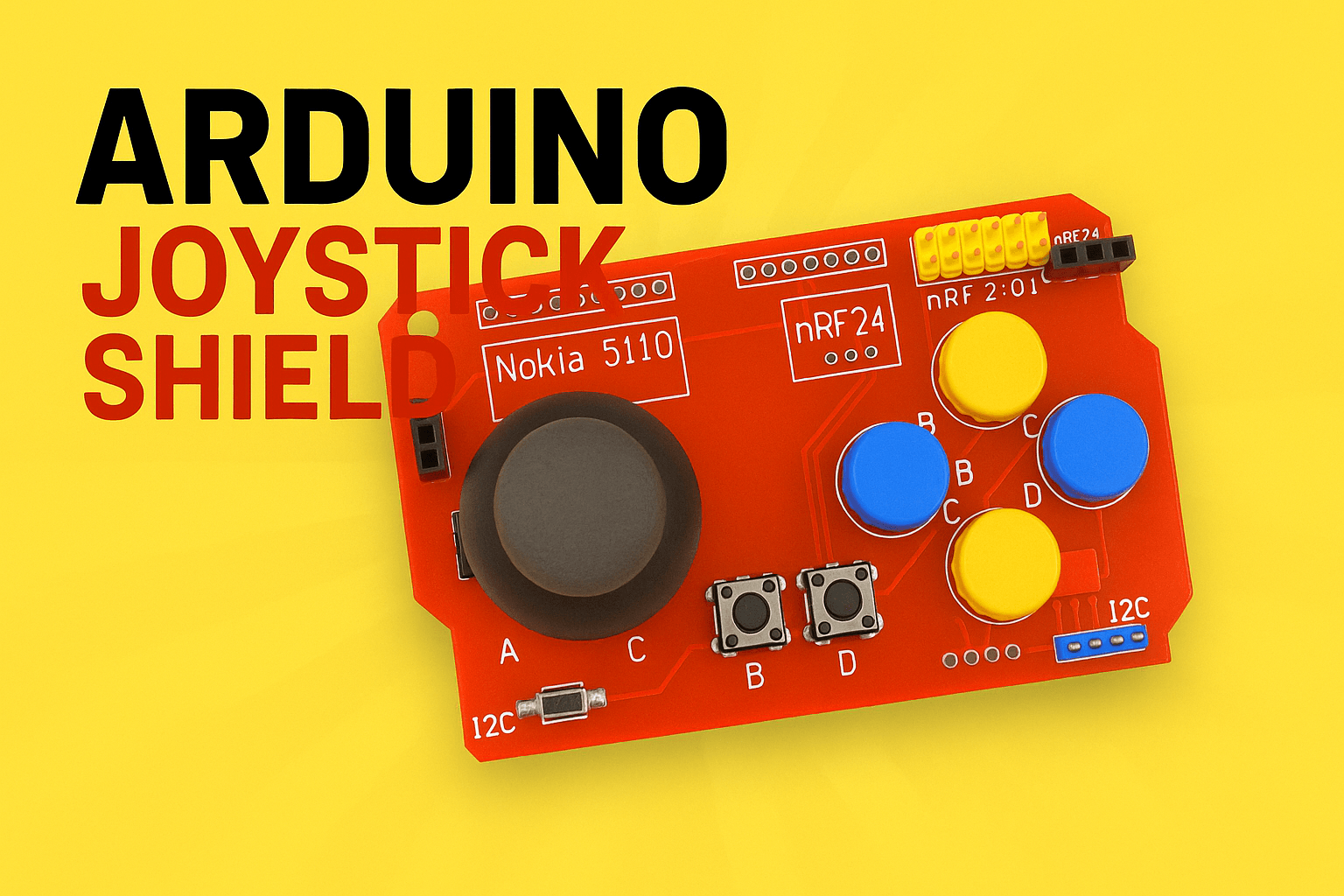

Arduino joystick shield

Quick and easy way to create joystick for remote controlled car

Quick and easy way to create joystick for remote controlled car

My small test board with WCH ch32v003

PCF8574 I2C Level shifter for LCD

scanning trough I2C bus to get all devices addresses

Simulate simple LCD display with hitachi controller(HD44780).

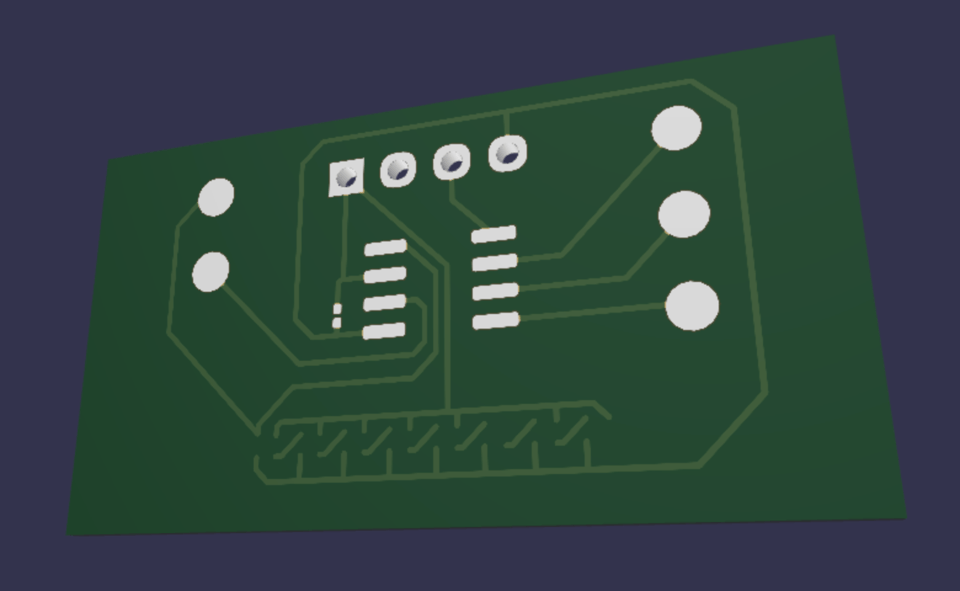

I tested out online PCB design tool